|

| October 22, 2013 | Volume 09 Issue 40 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Printable pressure switches used for variable speed control in new electric drill design

At Peratech, touch technology is a sensitive subject. It's how the North Yorkshire, U.K., company makes its money: creating printable ink-based, ultra-thin pressure-sensing Quantum Tunnelling Composite (QTC) technology and licensing it to other companies to incorporate into their products.

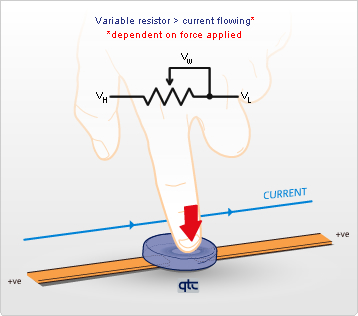

What's QTC? It's a composite material made from conductive filler particles combined with an elastomeric binder, typically silicone rubber. This material has the unique ability to smoothly change from an electrical insulator to a metal-like conductor (i.e. change its electrical property) when placed under pressure. This means that it can be used as a solid-state switch. This transition is influenced by how much deformation the material is experiencing as a result of the applied mechanical pressure, which means that, as a switch, it can display variable resistance. This enables pressure sensors to be created that function as on/off switches or with a resistance change proportional to the pressure applied. The sensitivity can be fine-tuned to suit the application: from being so sensitive that QTC materials can sense pressure through glass for touchscreen applications to ultra-rugged designs for military use. QTC Material is mechanically strong, has no moving parts to wear out, and can be easily integrated into existing products to enable force-sensing opportunities and solutions.

Under compression, tension, or torsion, the resistance of the QTC Material drops gradually and controllably. The material can also pass high currents.

One of the latest licensees (and first-time user) of Peratech's QTC tech is Global Power Brands International of Australia. Its first product to feature QTC sensors is its new Touch 12-V portable electric drill, which was just launched in September.

"The look and feel was a critical part of the design," says Peter Hosking, head of Globalpower. "QTC touch technology enabled us to create a really intuitive, touch-control interface that is very responsive with the slightest changes in pressure on the sensor, instantly changing the speed of the drill. Peratech's touch technology forms the very core of the design and our marketing of the new Touch drill.

"The drill is also designed to be used in the toughest of conditions with a five-year warranty, so we needed to have a switch that was ultra-reliable. QTC sensors have no moving parts, so they have a very long operational life and are proof against the dust, dirt, and liquids that always go hand in hand with drilling."

The new Touch drill from Globalpower uses a QTC switch for the variable speed control.

Making new strides

For Peratech, innovation is an ever-evolving process.

"We are developing a new range of QTC inks with the assistance of the U.K. Centre for Process Innovation," says David Lussey, Peratech's CTO. "These new inks enable QTC switches and sensors to be printed using standard printing techniques. This makes them very easy and inexpensive to mass produce, plus they can be printed at the same time as other printed electronic components onto plastics, textiles, etc. QTC pressure sensors are the next generation of switch and sensor technology that can be used in a wide variety of control interface applications ranging from touch screens and white boards to vehicles and household goods."

Interestingly, Peratech makes extensive use of U.K. government grants to help fund new research and development into Quantum Tunnelling Composites. As a result, there are three PhD students working on this area of material science along with two University laboratories.

"This is all done on a commercial basis," says Lussey. "It helps Peratech develop the whole area of QTC material science much faster than we could do on our own. Thanks to this government funding, we have doubled the number of patents that we are filing every year. This will really accelerate our presence in the market so that, within 10 years, QTC technology could be in almost every electrical and electronic device providing innovative, ultra-reliable, human machine interfaces." The company repors that it is profitable, with 100 percent of sales being to overseas customers.

Learn more at www.peratech.com.

Source: Peratech

Published October 2013

Rate this article

View our terms of use and privacy policy